About Pioneer-Dietecs

Founded in February 1995, Pioneer-Dietecs is a private company with a family history of over 100 years in the diemaking industry. Pioneer develops custom turnkey die-cutting systems consisting of both dies and presses for a variety of industries and applications.

Pioneer designs and engineers all dies and presses with a core of key employees and state-of-the-art equipment, providing quick turn-around times at minimal cost. Pioneer also provides a 24-hour turnaround for sharpening and die re-certification.

Our state-of–the-art equipment coupled with a strong engineering team and a proven track record allows us to provide customers with custom die-cutting systems designed and built to do each job perfectly, on time, and within budget.

What makes us different?

As leaders in innovation, Pioneer-Dietecs can optimize your die-cutting process by helping you find the best tool and the best press for your material, job quantity, and budget. Working with a company that builds both cutting dies and press systems makes all the difference when it comes to getting your parts cut right.

Pioneer helps you stay on top of the die-cutting industry by constantly striving to stay there ourselves. We are not another “head in the sand” die shop. We’re always out there working the shows and traveling the world to bring you the best solutions for your die-cutting applications. Unlike most online die suppliers, we enjoy working directly with you on a one-to-one basis. Call and see for yourself. Let us be your company’s cutting technology experts.

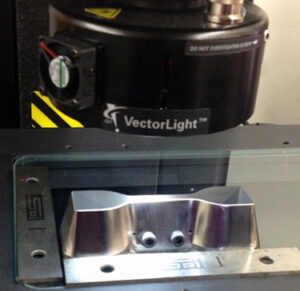

Precision-Engineered Specimen Dies

Pioneer-Dietecs Metrology Lab features a state-of-the-art CNC computerized measuring machine (CMM) for die inspection and certification to produce precision dies that perform consistently. CMM checks tolerances to 0.0001″, the tightest in the die-cutting industry. Certification is per ANSI/NCSL Z540-1, and meets ISO 17025;2005 specifications. Pioneer certifies dies’ dimensional tolerances to 0.002″ and maintains a perpetual archive of each die’s history.

Complete Die-Making and Die-Cutting Engineering Services

- Product measurement utilizing the latest 3-D CMM digitizing equipment

for reverse engineering of trim line surfaces - CAD computer aided die & tool designing utilizing AutoCAD

- Material identification and cut testing

- Cutting die type selection and specification

- Existing tooling trouble shooting, modification, and sharpening

- Cut part diagnostics, tolerance, and part accuracy guidance

- Cutting die design services and consultation

- Die ejection and cut quality advice

- Complete die cutting system specification, design, and manufacture

- Die cutting press pressure and cutting surface consultation

For more information about Pioneer engineering services, call us at 781-682-7900 or request a quote.

Facilities List

Pioneer-Dietecs’ manufacturing facility features CNC Vertical Machine Centers and CNC Traveling Wire EDM Centers for close tolerances and repeatability on the x, y, and z axis of die blades. Our Metrology Lab features a state-of-the-art CNC computerized measuring machine (CMM) for die inspection and certification to produce precision dies that perform consistently. Certification is per ANSI/NCSL Z540-1, and meets ISO 17025;2005 specifications.

Association Memberships

Pioneer-Dietecs belongs to the following associations:

- American Society for Testing and Materials (ASTM)

- International Association of Diecutting and Diemaking (IADD)

- European Diemaking Association (EDA)